A long time ago, an old man once told me, “if you think you know everything there is to know about transmissions, it’s time to find a new profession.” At the time, I didn’t really know what he was talking about, I honestly thought, how much is there to know? After a few years, I realized what he was talking about. From two speeds to ten speeds, adding electronics, and integrating the computers with the solenoids inside the transmission, just keeping up with the evolution of transmissions can be a full-time job.

The majority of new products, part upgrades and software updates come with some kind of document that states what it is for and why it was done. The rest, we learn through hands on experience. Even without documentation, most parts, once in hand, are easy to identify what the change was, and what it is for. Software opens up a whole new chapter. Most of the time, manufacturers do not disclose what all is done to software updates, only that it addresses shift quality, false codes, and other customer complaints. Rarely is anything disclosed about the coding that controls solenoid apply, timing, and various other operations inside the computer to control the transmission. Which often leads to having to find other avenues to locate information to help us properly diagnose various transmission shift quality concerns.figure 1: data view

Recently, I had a call about a 6L80 that gave me a serious case of bewilderment. Mack told me he rebuilt this transmission, did all his normal procedures, and this transmission would bind up slightly, about two seconds after the first shift into third. The transition from second to third was flawless. After that, you could drive it all day and not experience the bind again, until you cycled the key. And this was very consistent, every time he cycled the ignition, the bind would occur again shortly after the transmission shifted into third. It would never happen again until he shut it off, and started it, didn’t matter if it was immediately, or overnight.

As we discussed the possible causes of this, we went through the standard process of elimination. Since this was after the shift, things such as clutch clearance, sprag rotation, or cross leaks in the gear train was off the list. Narrowing it down to problems with the valve body or TECHM. We had a hard time believing anything in the valve body, such as broken springs, stuck valves or cross leaks, could be affected by cycling the key. This has to be a command issue the computer’s software, or so we thought.

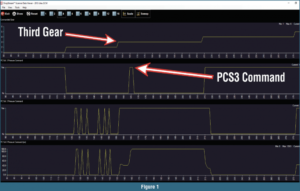

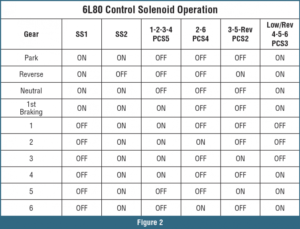

Mack hooked up his scan tool, took the vehicle for a test drive and recorded a movie of the event. He found that the computer was commanding the pressure control solenoid three on for a split second shortly after the shift into third and could see the pressure switch activating as well. The computer was commanding this, the valve was stroking, he could see the pressure switch activating. And this did not occur again throughout the entire drive, until he shut the vehicle off, and restarted it. I was absolutely sure this was some kind of software issue. I looked for software updates or bulletins related to this problem and found nothing. I also could not find anything stating this was normal operation for the solenoid after the shift into third. Even the solenoid application chart from the GM manual did not show this

At this point, I was ready to condemn the software, and ready to recommend looking into updates. Fortunately, Mack had another vehicle at his shop with a 6L80 that was close to the same year as the current vehicle he was working on, and it was operating normally. He hooked up his scan tool to monitor solenoid operation and went for a test drive. To our surprise, pressure control solenoid three was being pulsed on for a split second, but without the bind up. Apparently, GM wrote in the coding to have the computer pulse the pressure control solenoid three in third during the first shift cycle only, to charge the circuit for the 4-5-6 clutch to prepare for the third to fourth shift.

Now thoroughly confused, with no direction to go from here, I was ready for a reflash.

Mack asked if I thought the clutch clearance being too tight could cause this. I did not see how, since the shift from third to fourth did not bind. With lack of direction at this point, all we could do is open it up and look. He requested the clutch clearance specification and removed the transmission to inspect it.

He found the clutch clearance was .040” due to incorrect assembly, specifications are .050” – .074”. He corrected the mistake, now the clearance was .065”. He installed the transmission, and it shifted like a brand new one. No more bind in third when pressure control solenoid three was commanded on to prime the 4-5- 6 circuit. Mack tried several times to get the problem to reoccur, cycling the key, and the bind never returned. The software adapted to the tight clearance for the third to fourth shift, so it felt normal. There was no provision in the software coding to adapt to the clearance during the circuit charge, so when it did this, the clutches would make contact and Mack could feel a slight bind up.

Years ago, I would often get in a hurry to get a transmission off my bench and into the customer’s car. Sometimes I would skip using the proper tools, and doing the procedures like torquing bolts, measuring endplays, or checking clearances with a gauge, often doing things by eye and feel. Most would go out the door and work, some might have issues with shift quality or longevity, but old transmissions were much more forgiving than modern computers. The coding in a computer is written with specific parameters in which it can operate. The coding is written to adapt to some variations, but it has its limitations set by the writer. Solenoid feed rate, orifices, clutch clearances, and even fluid viscosity are considered to set these parameters. Anything not within specifications, that exceeds the parameters set by the coding, can result in poor shift quality and other abnormalities and trouble codes. A fresh reminder of why it’s important to follow the directions. Remember to set our clearances and endplay with gauges, and torque our bolts to specifications, to keep those transmissions from landing back on the bench.